Tiny robots that work together like ants could lead to a new way to manufacture complex structures and electronics.

- By Tom Simonite on April 16, 2014

Why It Matters

Existing mass production technology is inflexible and still relies on humans for many tasks.

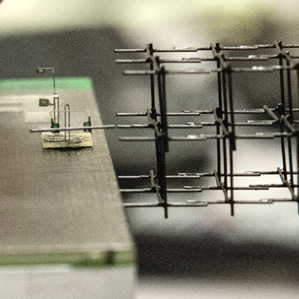

Building big: A team of three small, magnetically steered robots worked together to build this structure from toothpick-sized carbon rods. Someone glancing through the door of Annjoe Wong-Foy’s lab at SRI International might think his equipment is infested by ants. Dark shapes about a centimeter across move to and fro over elevated walkways: they weave around obstacles and carry small sticks.

A closer look makes it clear that these busy critters are in fact man-made. Wong-Foy, a senior research engineer at SRI, has built an army of magnetically steered workers to test the idea that “microrobots” could be a better way to assemble electronics components, or to build other small structures.

Wong-Foy’s robotic workers have already proved capable of building towers 30 centimeters (two feet) long from carbon rods, and other platforms able to support a kilogram of weight. The robots can work with glass, metal, wood, and electronic components. In one demonstration, they made a carbon truss structure with wires and colored LEDs mixed in to serve as the lab’s Christmas tree.

“We can scale to many more robots at low cost,” says Wong-Foy, who thinks his system could develop into a new approach to manufacturing. Many electronic components are the right size to be handled by his microrobots, he says, and teams of them might prove a good way to lay them out onto circuit boards.

SRI wants to create a version of the microrobot system that could be sold to other research labs and companies to experiment with. “We’ve demonstrated the basic platform and are now looking at how we can transfer out of the lab as a research platform,” says Rich Mahoney, director of robotics at SRI. “You should be able to buy this on the shelf.”

SRI’s microworkers are simple: just small magnetic platforms with simple wire arms on top. They can move only when placed on a surface with a specific pattern of electrical circuits inside. Sending current through the coils beneath exerts a force on the magnets and steers the robots around. Wong-Foy has written software to do that, and used it to choreograph the movement of over 1,000 tiny robots in a complex circulating pattern. That shows it should be possible to have them work in large teams, he says.

The robots’ wire arms are unable to move independently. But creating teams of robots with different types of arms makes it possible to do complex work.

Building a truss structure requires three types of workers. One operates a kind of toothpick dispenser, pushing a lever to release a toothpick-sized carbon rod. Another robot dips its arms into a water trough to put droplets on the ends of its arms, and then uses surface tension to pick up the rod. A third robot visits a glue station, dipping its arms and then applying the glue to the structure under construction. Finally, the robot that picked up the rod presses it into place and waits for an ultraviolet light to switch on to cure the glue. Then it can withdraw to pick up a new rod.

The software controlling the robots can also move the platform they are sitting on. It moves the platform each time a new layer is complete so the robots’ working space stays the same as the structure they’re building grows.

Much like 3-D printing technology, microrobots promise to be a more efficient way to make complex objects in small quantities than conventional mass-production technology, says Mahoney. That’s partly because the microrobots can be reprogrammed to do completely new tasks, and partly because they’re inexpensive. “We sometimes call this megahertz manipulation,” he says. “We can think of manipulation at rates we’re used to seeing in information processing.”

Helping to make circuit boards in small batches for prototyping new electronic devices is one possible application. Hobbyists and small companies working on electronics hardware today make few prototype circuit boards due to the time it takes to assemble them by hand, and the expense and delay of paying for small runs at dedicated plants.

Wong-Foy also thinks his approach might be useful for assembling devices that combine electronic and optical components, for example to interface with fiber optic cables. Because silicon and optical components can’t be processed in the same step, that industry often uses manual assembly to put them together. “In the field of optical electronics people have not found a good way to integrate indium phosphide lasers with silicon components,” says Wong-Foy. “The scale of those things is the size of carbon rods we’re using here.”

Nenhum comentário:

Postar um comentário

Observação: somente um membro deste blog pode postar um comentário.