Equipment for making microchips has led to solar cells that are twice as efficient as conventional ones.By Kevin Bullis on December 16, 2014

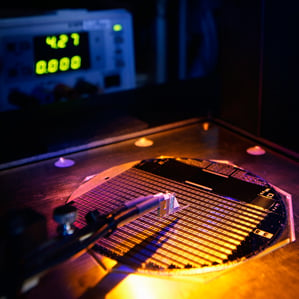

A wafer bearing 500 tiny solar cells, made by Soitec, has produced a new world record. Soitec, a French manufacturing company, says it has used techniques designed for making microprocessors to produce solar cells with a record-setting efficiency of 46 percent, converting more than twice as much sunlight into electricity as conventional cells. Although the cells are more complicated to produce, using established manufacturing techniques promises to keep production costs down. Ordinary solar cells use one semiconductor to convert sunlight into electricity. The cells made by Soitec have four semiconductors, each designed to target a different part of the solar spectrum. Soitec produced its first four-semiconductor cell about a year ago. Since then, it’s been improving efficiencies rapidly, and it looks on track to be the first company to hit the long-awaited milestone of 50 percent efficiency. Over the last several years, the costs of solar power have come down by over 80 percent, mostly because companies have found cheaper ways to manufacture conventional silicon solar cells. But solar power is still more expensive than fossil fuels in most places. Soitec is one of several companies attempting to lower costs by making solar cells more efficient, so fewer are needed to generate the same amount of power. That cuts installation costs, which can account for more than half the cost of solar power (see “Solar Panels That Configure Themselves”). The challenge is achieving high efficiencies without significantly increasing the cost of making the cells. Combining multiple semiconductors in a solar cell is an old idea that’s hard to execute in practice. It is possible to grow the semiconductor materials separately and then bond them together, but that requires multiple crystalline templates, which is expensive, and it can result in imperfect bonds. To make its four-semiconductor solar cells, Soitec starts by growing two atomically compatible semiconductor materials on one template and two different compatible semiconductors on another. One of the templates is then removed so it can be reused (the structure of the final solar cell makes it difficult to remove the other one). Finally, the two pairs of semiconductors are stacked together. Soitec has already used the process of reusing the template and bonding the semiconductors for years to make components for microprocessors and other electronics. The company plans to begin high-volume manufacturing of its four-semiconductor cells in 2016. Some questions remain about how cheap its process will be, though. The company isn’t providing specific estimates for the cost per kilowatt of solar power using its technology, saying the numbers depend on location. Other companies are vying to be the first to reach 50 percent efficiency. This year the startup Semprius demonstrated four-semiconductor cells that were 44.1 percent efficient, and the company says it’s on track to break the world record next year. source : MIT Technology Review |

Nenhum comentário:

Postar um comentário

Observação: somente um membro deste blog pode postar um comentário.